Your cart is currently empty!

Sleeping Bag Design Features

Along with quality materials and workmanship, our design features set our sleeping bags apart from all others. Our hood openings are more contoured in shape so that even at rest the sides of the hood lie closer to your face. We build the differential into our mummy bags so that the shell fabric “breaks” to create better loft across the width of the bags. The V-Block Side Baffle found in our winter bags ensures positive down control on the top, bottom and along the sides of the bag. Our ExtremeLite™ bags use the newest, most compressible and lightest weight fabrics available. All of these design features are intended to give you a well functioning bag that will last a long time.

About our Products

With over 30 bags to choose from we have made it easier for you to choose the best fitting bag. Start by judging your body size, or what kind of room you need to stay comfortable throughout the night. Our wide cut semi-rectangular bags are named after North American Forest Trees. This is the choice for people needing lots of room regardless of weight. Some of these bags feature hoods. Our wide cut mummy bags run 62” to 66” in shoulder girth and are named after North American Mammals. This is the standard cut bag for most lightweight mountaineering. We also have a series of narrow cut mummy bags and they are named after our North American Indian Tribes and Nations. These bags provide the most savings in weight and are the most temperature efficient. They are extremely compressible, making them easier to carry around. Our ExtremeLite™ bags are easily identified by the suffix “Lite”. These are the lightest weight bags available and are meant for those activities when extreme compressibility and weight are an issue.

Reverse Differential Hood

Our hoods are cut so that the inside of the hood is made with a larger piece of fabric than the outside. This creates a hood with loose down filled fabric which surrounds your head. That way you can enjoy warm insulation around your head and face without having to cinch the hood tight. Also, the extra fabric can be adjusted to create a down filled ruff or bill across your forehead.

Differential Cut

Mummy bags are made with an inner shell fabric cut narrower than the outer shell. This is called differential. Its purpose is to give the inner shell a smaller circumference than the outer shell. This eliminates extra fabric inside the bag that could lead to cold spots. Most of our mummy bags are differentially cut to promote proper lofting and to protect against down compression when knees or elbows push against the inner fabric. Semi rectangular bags are not cut this way so that they can be unzipped to lay flat.

Continuous Baffles

A 3-season bag needs to serve in a wide range of temperatures. You will expect it to provide comfort during the heat of summer through the cooler temperatures of fall or early spring. To ensure a broad temperature range we build our 2 and 3-season bags with continuous baffles which encircle the bag from zipper to zipper. This allows you to shift the down insulation from one side of the bag to the other. During hot summer nights, you could shift the down from the top of the bag to the bottom so there is less insulation on top of you. When the weather is cold, you can move the down to the top of the bag. Just open the bag flat and push the down with your hands from one side to the other. This adjustment allows you to maintain a comfortable temperature inside your bag. We sew continuous baffle bags with 5 1/4″ baffle spacing so that unintended down migration during the night is kept to a minimum. Our continuous baffles are fixed to the material in a “slant box” configuration because it provides the best distribution of down across the width of the bag given the differential cut.

Sleeping Bag Fill & Construction

Added together, it’s all these little details that make a great sleeping bag and push Western Mountaineering over the top! For instance, all of our winter bags with the Full Down Collar are made with Interlocking Double Draft Tubes. When the bag is zipped these large stoutly filled tubes rest side by side rather than on top of each other. That way these Interlocking Draft Tubes retain their full loft without being compressed as the zipper closes. When a bag has a single draft tube it will hang from the top so that the zipper won’t inadvertently be exposed while moving inside the bag. A Dacron stiffening tape is sewn alongside each zipper to prevent snags. Our Hook and Loop closures are backed with fabric to prevent fraying and are placed on non-integral parts of the bag like the draw cord casing.

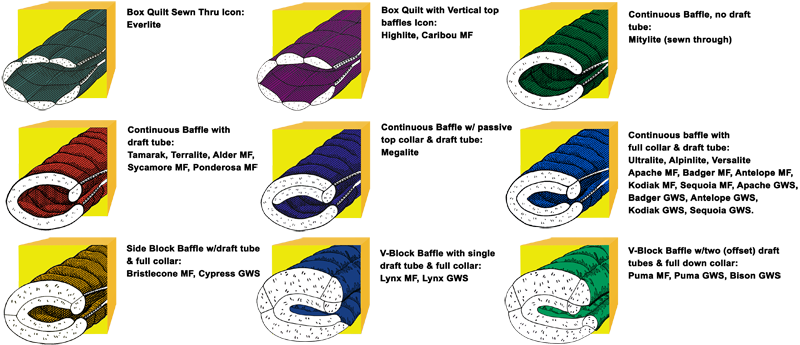

We have created a series of icons that represent features found on Western Mountaineering sleeping bags. At a glance you will be able to tell which bags have single or double draft tubes, passive or full down collars, continuous baffles and the type of side block baffle. These icons appear throughout the catalog for each sleeping bag.

Materials

Why We Choose Down

Since our beginning, Western Mountaineering has always felt that high fill power goose down is the best insulation material available. This natural fiber, while highly variable in nature, provides more warmth per ounce than any other material. Down’s unique structure is responsible for its tremendous ability to trap warm air. Its filaments are divided and sub-divided to reach out into its surroundings to create a dead air space that slows the movement of warm air. By its very nature, a down filled sleeping bag is as much as 35% lighter than its synthetic counterparts. It is more compressible than synthetic insulations and provides the most warmth with the least bulk. Down also is known to have the greatest longevity, and it will outlast any other insulation by 3 to 5 times, making it the most economical choice after its initial investment. Down sleeping bags drape luxuriously over the body and ensure good coverage and warm contact. There is nothing else like down.

Fill Power Testing

To perform a certified test, a sample of down is sent to an independent laboratory. There the sample is placed in a large screened box and allowed to condition for 5 days before being tested. During this time the sample is stirred, mixed, and blown with a warm hair dryer. This conditioning is intended to stabilize the sample so that consistent results may be obtained. Then a 1 ounce sample is drawn and placed into a measuring cylinder. A piston weighted to 68.4 grams is placed on top of the down and when it comes to rest the volume of the down is measured in cubic inches. In spite of 5 days of conditioning, the laboratory will publish their results with a plus or minus 5% error. This is a full 10% range and for an 850 fill test, results in an 80 point variance! Furthermore, conditioning actually improves the sample by drying and blowing out dust and other small particles while the down at the factory remains unconditioned! This is what we mean by an Optimistic fill power rather than a Practical fill power rating. If two bags have the same internal volume, the bag with more loft will be warmer.

If two bags have the same loft, the bag with the smaller internal volume will be more efficient and warmer. If two bags have the same loft and internal volume, but one has a lot more down fill by weight, then check the density of down inside the chambers and the fill power claimed by the manufacturer. Well filled down chambers provide better down control.

850+ Fill Power Goose Down

Western Mountaineering uses the highest lofting premium goose down available for all of our sleeping bags. Our fill power claim of 850+ is meant to be a realistic estimate given the variability of the product and the nature of fill power test methods. In reality, our certified tests most often are higher than what we claim. This is because the certified test methods provide the most optimistic fill power rating and do not represent what is being put into your sleeping bag. Recently, these testing methods for fill power changed again making the fill power ratings even higher. Now, each sample of down will receive a tumble dry before it is given several days to loft up in a perfectly controlled environment. During that time it is enhanced by using a blow dryer to boost loft. Your sleeping bag will never receive that kind of treatment, and this is why we claim a more practical fill power. Rest assured, we use only the finest goose down available.

ExtremeLite™ Fabric

Our search never ends for the lightest weight downproof fabrics to feature in our special use ExtremeLite™ bags. For these bags we have worked with suppliers to develop extremely high thread count fabrics with ultra lightweight yarns not seen in the sleeping bag market before. These fabrics are constructed from yarns that are 12 denier or finer with up to 420 threads per square inch. Our ExtremeLite™ series features 8 models which weigh between 16 ounces and 2 pounds! These bags are designed for special applications where compressed volume and weight are critical factors. Although some durability is sacrificed with these lighter fabrics, our ExtremeLite™ bags are perfect for the lightweight specialist. Our lightest weight jackets and vests also feature a very lightweight shell fabric. These materials weigh less than 1 oz. per square yard, allowing us to make some of the lightest insulated garments you will find. Extra care should be taken to avoid tearing or abrasion damage to products made with these specialized lightweight fabrics.

MicroLite XP™ Fabric

Our new 20 Denier MicroLite XP™ microfiber reduces the total weights of the bags in this series by 15 to 20 percent! It is the highest threadcount fabric we have ever used with over 400 threads per square inch. We have worked closely with our supplier to develop this new fabric which is highly water resistant, highly breathable, and very light weight. Its hard to imagine a more impressive combination of performance characteristics in a shell fabric.

What Is Microfiber?

A microfiber fabric is very water resistant because of its combination of high thread count and makeup of dense yarns. Each micofiber yarn has many more filaments than a normal nylon or polyester yarn of equivalent size. Woven into high thread count material, it becomes a fabric that really keeps wind and water out. Since there is no coating or laminate on the material, it is highly breathable. The fabric construction is responsible for weather proofness, it’s not something that can wear off, wash out or delaminate. This is the most technologically advanced non-laminated weather resistant fabric available. Look for bags with a microfiber shell if you expect some contact with moisture.

Gore Infinium™ Fabric

Our Gore Infinium™ fabric, manufactured by W.L. Gore and Associates, is the most weather resistant/breathable fabric available and provides the ultimate protection against moisture and condensation. The face fabric is a 273 thread count 30 denier fabric that weighs 1.1 ounces per square yard. This is the lightest and most compressible Gore Infinium™ fabric available and the one with the softest hand. After laminating, its finished weight is about 1.7 oz. per yard. The breathability of the Gore Infinium™ membrane reduces the threat of condensation while remaining plenty water resistant for the needs of a sleeping bag. Use Gore Infinium™ sleeping bags in damp or extreme conditions to prevent moisture from reducing down performance. Some winter conditions may require the use of the Hot Sac VBL (Vapor Barrier Liner) to provide optimum performance and heat retention.

StormShield™

Introducing StormShield™, our state of the art, two-layer membrane waterproof fabric, designed to keep you shielded from the elements, without weighing you down. Extremely water resistant, breathable and light weight, StormShield™ combines a cutting-edge laminated shell fabric with a PFAS/PFC free DWR treatment for durable and lightweight water proofing. StormShield™’s face fabric is a durable, tear resistant 15-denier nylon mini ripstop, treated with a C-Zero PFAS/PFC free, environmentally friendly DWR treatment. The inner layer is a hydrophobic microporous membrane, breathable @ 35,000g/SGM MVTR with a waterproofness rating 10, 000mm +. With a finished weight of just 54 grams per square meter, StormShield™ offers unparalleled performance in a light weight state of the art fabric.

YKK Zippers

We use a #5 YKK coil zipper with two dual direction pulls and locking head. This zipper is lighter weight and less bulky than the old #7 zipper. The coil construction has a less abrasive surface in the event of zipper snags and provides years of trouble free operation.

Baffle Material

Pre-cut no-see-um netting is what we use for all internal baffles. This material is firm to prevent distortion, but flexible enough to insure compressibility. It is extremely lightweight and durable.

Water Repellent Treatments

All of our fabrics are finished with a PFAS-free DWR (Durable Water Repellent) that is rated as 80/20. This is an industry measure of durability that suggests that 80% DWR is retained after 20 washings. In reality this rating is for laboratory test procedure only and is not realistic for home washing. While all of our fabrics are reinforced with DWR, we recommend reapplying DWR throughout the lifetime of the product to reinforce its water resistance and breathability.

Abrasion Resistant Taffeta

We use a more durable fabric at the foot sections of our three expedition Gore Infinium™ bags. This material is woven with heavier yarns so the inside of your bag is protected when you store gear or boot liners at the foot of your bag. The Gore Infinium™ logo is a registered trademark of W.L. Gore & Associates. Inc.